High-Purity Engineering Plastic Solutions

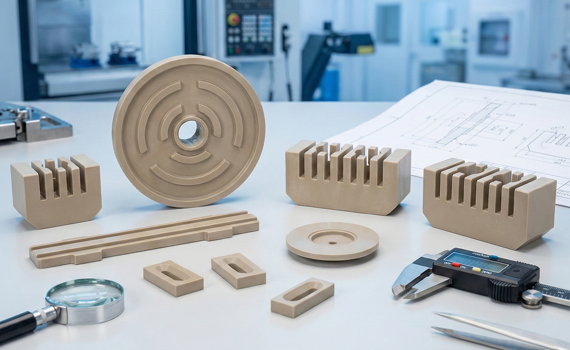

Specializing in high-performance material development, precision CNC, and surface grinding technologies to meet the demands of rigorous manufacturing processes.

We offer integrated services ranging from material selection and precision CNC machining to surface grinding. Our expertise in Tolerance Control ensures that our plastic components exhibit exceptional dimensional stability and surface cleanliness—crucial for applications involving vacuum suction, high-seal valves, and precision transmission.

In modern manufacturing, where extreme cleanliness and lightweighting are paramount, "replacing steel with plastic" has become a significant trend. We primarily operate on a "Build to Print" basis, performing precision machining according to customer specifications. Additionally, we fully support R&D teams with low-volume prototyping, development, and testing. When working with high-performance engineering plastics such as PEEK, Vespel, and PCTFE, we are dedicated to overcoming challenges related to material deformation. We assist you in achieving successful sample verification and seamlessly transitioning into mass production.

Our Service Scope

We specialize in the deep processing of semiconductor-grade special plastics, providing optimal processes tailored to different shapes and application requirements:

Specializing in mill-turn compound machining of high-unit-price materials like PEEK, Vespel (PI), Torlon (PAI), PCTFE, and PBI. For irregularly shaped parts (e.g., transmission forks, shaped suction cups), we use special clamping methods and strategies to effectively overcome deformation challenges, ensuring assembly requirements are met.

Providing precision grinding for flat parts (e.g., insulation gaskets, carriers) to deliver excellent flatness control.

Providing machining services for ESD materials like conductive PEEK. Familiar with electrical specifications of various materials, we can suggest the most suitable material based on your impedance requirements.

Leveraging extensive plastic machining experience, we adjust machining parameters and clamping methods according to different material characteristics to effectively overcome plastic deformation issues, ensuring dimensions meet drawing requirements.

Core Advantages (Why SY Tech?)

1. Expertise in Hard-to-Process Special Materials

From extremely soft and easily deformable PTFE to extremely hard and brittle Vespel, we possess a rich database of tool parameters. For PCTFE, a key material for low-temperature high-pressure valves, we have mastered tolerance control techniques to ensure airtightness.

2. Flexible Support for R&D Development & Testing

Unlike general mass production factories that only accept large orders, we understand the needs of the R&D phase. Whether it is single-piece Prototyping or small-batch trial production, we are willing to work with engineers for repeated testing and modification, shortening your development cycle.

3. Specialized Surface Grinding Technology for Engineering Plastics

For flat parts with high airtightness requirements, we use a surface grinding process dedicated to plastics. Under ideal conditions, flatness can be controlled to around ±0.02 mm (Note: Tolerance ranges for shaped or irregular structural parts need to be evaluated based on actual part shape), solving airtightness and fitting needs that general milling cannot achieve.

4. Committed to Micro-Surface Quality (Fine Surface Control)

Through Tool Path Optimization and finishing parameters, we strive to achieve uniform and fine surface roughness (Ra). We perform detailed finishing on critical contact surfaces to ensure smooth finished surfaces, effectively suppress burrs (Burr Suppression), and reduce the risk of particle residue.

Solving Common R&D and Process Challenges

We assist you in solving various "physical challenges" in material applications:

| Common Field Challenges | Our Solution |

|---|---|

| R&D phase needs small-volume trials, cannot find a cooperative vendor | We fully support R&D low-volume, high-mix development needs, cooperating with drawings for rapid prototyping and test verification. |

| Insufficient flatness of vacuum suction cups or airtight parts | We employ PEEK surface grinding technology for flat structural parts, controlling flatness to the ±0.02 mm level (shaped parts require separate evaluation) to enhance airtight sealing effects. |

| Plastic parts loose dimensions after machining | We set optimal machining parameters and clamping methods based on material characteristics, reserving deformation compensation allowances to ensure the final product meets tolerance requirements. |

| Leakage in low-temperature or high-pressure gas pipelines | We recommend using PCTFE to replace standard PTFE. PCTFE possesses superior mechanical strength and low-temperature dimensional stability, making it the best choice for cryogenic valve seats. |

| Electrostatic discharge (ESD) causing product to attract dust | Based on anti-static requirements, we assist in selecting materials with appropriate resistivity (e.g., Conductive PEEK, Anti-static PEEK), ensuring the material itself complies with ESD protection standards. |

Applicable Industries and Scenarios

Not limited to semiconductors, we serve all fields requiring high-precision non-metal parts:

Wafer transfer Robot Blades, Vacuum Valve Seats, Insulation/Heat shielding materials.

Large Anti-static (ESD) transfer rollers, Glass substrate carrier blocks.

Black PEEK light-absorbing masks, High-precision insulation gaskets, Test fixture stages.

📘 Success Stories: Precision Machining Solving On-Site Pain Points

🛠️ Machinable Materials & Applications List (Material Capabilities)

We have extensive inventory and machining experience covering high-performance engineering plastics commonly used in semiconductor, optoelectronic, and medical industries. If the material you need is not listed here, please feel free to call us for consultation.

| Material Category | Common Material Names (Trade Names & Abbreviations) | Target Industries & Common Applications |

|---|---|---|

| Super Engineering Plastics (High Performance) | PEEK, PI (Vespel® SP-1), PAI (Torlon®), PBI (Celazole®), PPS |

🔹 Semiconductor Frontend, Vacuum Equipment, IC Testing App: Wafer Clamps, Chamber insulation parts, CMP Retaining Rings, IC Test Sockets, Vacuum suction cups. |

| Fluoropolymers (Fluoropolymers) | PTFE (Teflon®), PCTFE (Neoflon®), PVDF (Kynar®), PFA |

🔹 Wet Bench, Chemical Delivery, Gas Systems App: Acid/Alkali resistant tanks, Fittings, Cryogenic Valve Seats, Sealing gaskets. |

| Special Function Materials (Special Function) | ESD PEEK, Conductive PEEK, PEEK-GF30 (Glass Fiber Filled) |

🔹 Wafer Transfer, Optoelectronic Panels App: Anti-static Robot Blades, Wafer Cassettes, Trays, Conductive rollers. |

| General Engineering Plastics (General Engineering) | POM, PET-P, UPE (UHMW-PE), PC, PP, PVC, CPVC |

🔹 Automation Equipment, Inspection Instruments, Mechanical Transmission App: Rails, Gears, Insulation blocks, General fixtures, Various transmission parts. |

Consult Now / Contact Us

If you are looking for high-precision PEEK / Vespel Machining services, or facing machining challenges with special plastic materials (PCTFE), please feel free to contact SY-Tech .

You can also fill out the inquiry form below, and our specialists will serve you as soon as possible.

✉️ Email: service@sy-tech.com.tw

Combining the advantages of professional machining and service teams, we become your most trusted partner with precise engineering judgment and flexible execution.