Custom Manufacturing Solutions

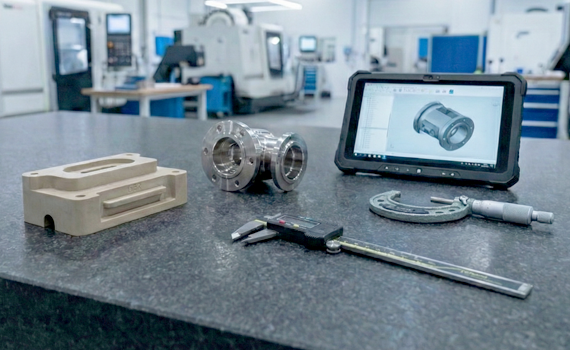

Delivering precise realization solutions for complex structures and specialized specifications.

We have established a highly resilient manufacturing network designed specifically to tackle the challenges of complex geometric structures and specialized materials.

Unlike standard OEM models that merely execute based on drawings, we introduce Design for Manufacturability (DFM) assessments in the early stages of a project. This allows us to help you identify potential risks and eliminate process bottlenecks before production begins.

To address the common needs for "multi-process integration" and "high-precision tolerance control" in custom projects, we integrate Turn-Mill (Mill-Turn), Electrical Discharge Machining (EDM), Grinding, and various Surface Treatment resources. From single-piece Prototype Verification to Pilot Runs, we are committed to bridging supply chain gaps and providing stable, industrial-standard deliverables. We are your most reliable long-term partner for product development and specialty component manufacturing.

Our Service Scope

One-stop cross-process manufacturing support to successfully realize your designs:

Supporting precision manufacturing needs for multi-axis machining, thin-wall structures, and freeform surfaces.

Specializing in engineering plastics (PEEK, Torlon®) and special alloys (Titanium, Inconel), with process parameter optimization to ensure dimensional stability.

Providing a highly flexible "High-Mix Low-Volume" manufacturing mode specifically for international clients, supporting export logistics and quality standard alignment.

Offering seamless process transition from high-fidelity Mockups to small-batch Pilot Runs.

Integrating Anodizing, Passivation, Electropolishing, and Plating services to ensure consistent final quality.

Core Advantages (Why SY Tech?)

1. Material Mastery

We possess deep expertise in the deformation characteristics of high-end engineering plastics and the machining challenges of corrosion-resistant metals. Through stress relief processes, specialized clamping design, and strategic machining sequencing, we effectively control deformation risks to ensure parts fall within design tolerances.

2. Flexible Capacity

Facing the fluctuating demands of custom projects, we can dynamically adjust production schedules and resource allocation. This represents not just equipment flexibility, but total supply chain integration, helping clients mitigate uncertainties caused by urgent orders or design changes.

3. Engineering-Grade Evaluation

Before production, every project undergoes a comprehensive DFM assessment. If high structural risks or unnecessary cost inefficiencies are identified, we proactively propose optimization suggestions to ensure the part achieves the best balance between "functional requirements" and "manufacturing efficiency."

4. Cross-Process One-Stop Integration

High-end products often cannot be completed by a single process. We integrate CNC Precision Machining, EDM, Grinding, and Surface Treatment for you. You only need to interface with a single point of contact to ensure smooth process transitions and clear accountability.

5. Rigorous Quality Inspection Standards

Even for low-volume custom parts, we maintain industrial-grade QA processes. Using high-precision metrology equipment, we ensure that Critical Feature Sizes and Geometric Dimensioning and Tolerancing (GD&T) meet drawing specifications, providing full inspection reports upon request.

Solving Common Manufacturing Challenges

We not only provide capacity but also assist you in overcoming production difficulties from an engineering perspective:

| Common Field Challenge | Our Solution |

|---|---|

| Complex structure; impossible with a single process | Integrating Turn-Mill and EDM technologies to break down processes and precisely achieve complex geometric features. |

| Plastic parts deform easily after machining | Implementing material stress relief processes and optimizing tool paths and clamping methods to ensure dimensional stability. |

| Fragmented supply chain; unclear accountability | Providing one-stop turnkey services, managing material sourcing, machining, finishing, and assembly under a single point of contact. |

| Low pilot run volume; low supplier support | Establishing a high-flexibility production mode for global clients, fully supporting verification needs during the R&D phase. |

| Difficulty combining heterogeneous materials | Providing "Metal × Plastic" composite design and assembly advice to resolve issues related to differences in thermal expansion coefficients. |

Applications & Target Sectors

Automation transmission mechanisms, high-precision slide rail accessories, complex linkages, and special joints.

Critical components for vacuum, high-temperature, strong acid/alkali, or high-wear environments (e.g., heat-resistant insulators, corrosion-resistant valve bodies).

Creating high-fidelity prototypes using Real Materials prior to mass production for structural testing and functional verification.

📘 Case Studies: Manufacturing Optimization & Quality Improvement

Immediate Consultation / Contact Us

If you have complex drawings that need to be realized, or if you are facing manufacturing challenges that your current suppliers cannot overcome, please contact SY Tech.

You are also welcome to fill out the form below, and our specialists will proceed with drawing evaluation and requirement confirmation.

✉️ Email: service@sy-tech.com.tw

We utilize pragmatic manufacturing logic and flexible resource integration to help you overcome production barriers and precisely transform your designs into market-ready products.