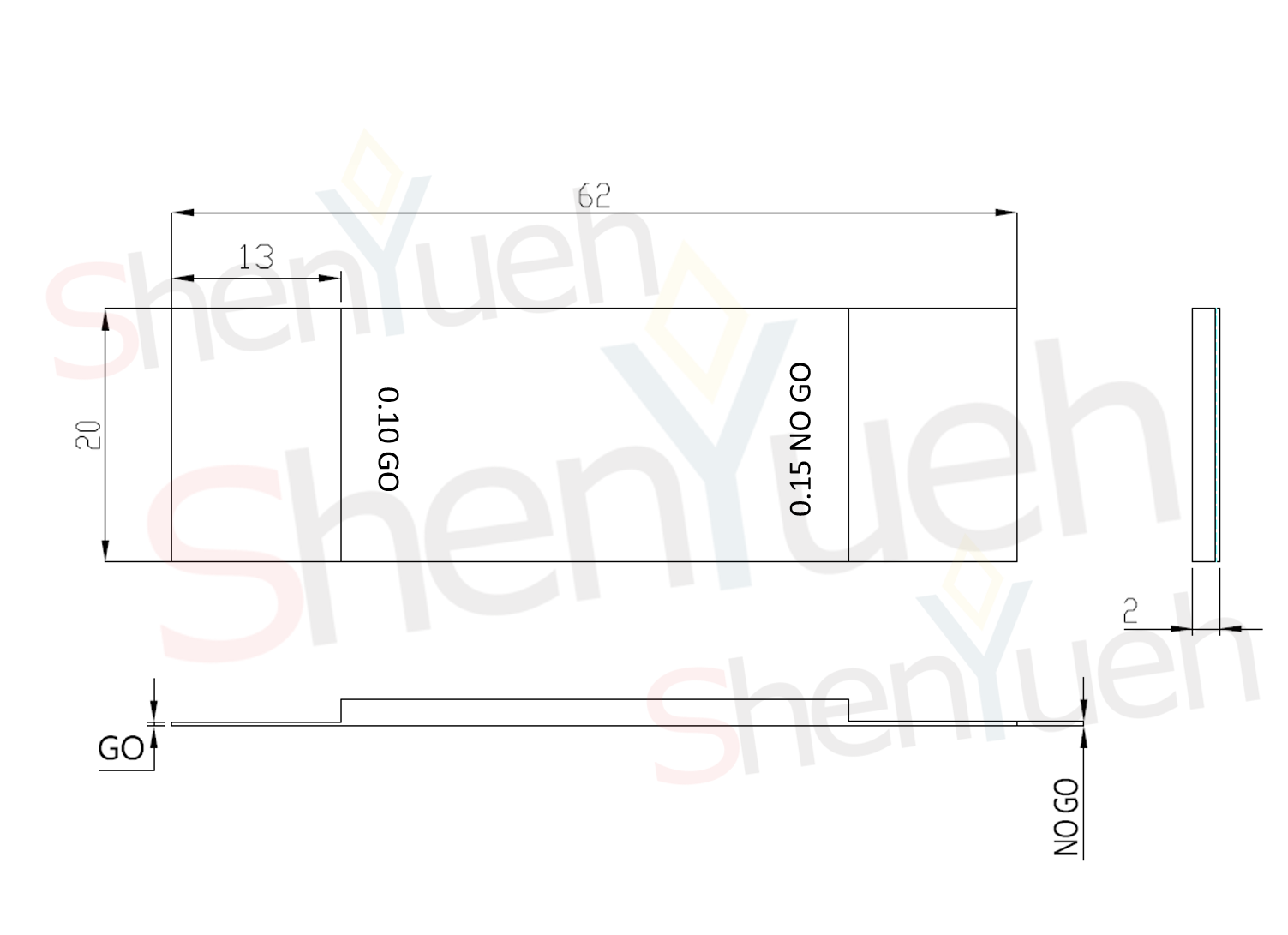

PEEK GO/NO-GO Plastic Gauge

We manufacture our PEEK GO / NO-GO gauges using high-cleanliness engineering plastic PEEK through precision machining. They are designed for gap acceptance checks, fixture assembly verification, and equipment maintenance measurements.

Compared with metal gauges, PEEK gauges can safely contact metal, plastic, and various surface-sensitive components without scratching or particle shedding. They also reduce the risk of contamination, making them especially suitable for high-cleanliness production lines in semiconductor, optoelectronics, and medical industries.

Product Advantages

- PEEK material does not scratch or shed particles, allowing safe contact with sensitive components.

- GO / NO-GO dual-step measurement provides clear acceptance judgment and intuitive operation.

- High cleanliness, low particle generation, and chemical resistance make it suitable for harsh process environments.

- The best achievable thickness accuracy can reach within ±0.01 mm.

- Optional color marking enhances identification and improves operational efficiency.

- Supports low-quantity production, inch sizes, and multiple custom thickness options.

Differences Between Metal Gauges and PEEK Gauges

Potential Issues with Metal Gauges

- Easily scratches the surface of workpieces

- Wear and particle shedding after long-term use

- Increases risk of foreign particle contamination

- Not suitable for sensitive or precision surfaces

Advantages of PEEK Gauges

- No scratching and no particle shedding

- Low particle generation, ideal for cleanroom environments

- Safe for contact with metal, plastic, ceramic, coating surfaces, and more

- More friendly for semiconductor and high-precision equipment applications

Applications

The PEEK GO / NO-GO Gauge is suitable for various precision measurement scenarios, including:

- Semiconductor processes and equipment PM maintenance

- Gap acceptance verification for C-Shroud, covers, and protective housings

- Optoelectronics and display module fixture measurement

- Precision equipment assembly acceptance

- Medical device machining and fixture verification

- Assembly acceptance inspection in general manufacturing

Common application example: 713-040075-020 (C-Shroud gap measurement)

Product Specifications

| Part No. | GO Thickness | NO-GO Thickness | Tolerance |

| SY-GNG-010-015 | 0.10 mm | 0.15 mm | ±0.02 mm |

| SY-GNG-015-020 | 0.15 mm | 0.20 mm | ±0.02 mm |

| SY-GNG-020-025 | 0.20 mm | 0.25 mm | ±0.02 mm |

| SY-GNG-030-035 | 0.30 mm | 0.35 mm | ±0.02 mm |

| SY-GNG-040-045 | 0.40 mm | 0.45 mm | ±0.02 mm |

※ Customized thickness, spacing, or dimensions are available upon request.

Customization Services

- Suitable for low-volume production, fixture development, and prototype runs

- Customizable thickness, spacing, and dimensions

- Optional color marking (different colors for GO / NO-GO)

- Supports inch-size specifications for overseas equipment

Contact Us

If you are evaluating gap acceptance, fixture fit, or require customized thickness, feel free to let us know your requirements.

We offer low-volume production, inch specifications, and flexible thickness customization, and will assist you in quickly confirming feasibility.

For more information or a quotation, please fill out the form below and we will reply as soon as possible.

Our plastic PEEK GO/NO-GO gauges offer excellent chemical resistance. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, PEEK GO/NO-GO Plastic Gauge, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.