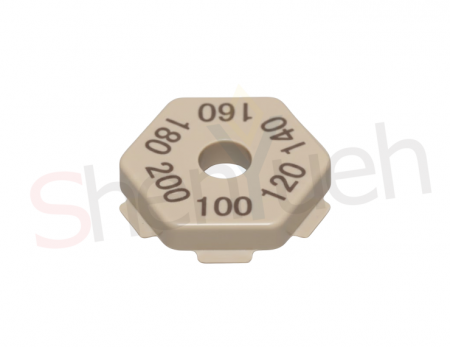

PEEK Hexagonal Feeler Gauge

Our PEEK hexagonal feeler gauge is precision-machined from high-quality engineering plastic PEEK (Polyetheretherketone). The unique hexagonal design integrates six commonly used thickness values into a single tool, making it ideal for mold gap inspection, wafer flatness verification, and precision mechanical assembly. This design eliminates the need for frequent tool changes, significantly improving measurement efficiency and on-site workflow.

Compared with traditional metal feeler gauges, PEEK offers excellent wear resistance and high-temperature performance, with carefully controlled hardness to reduce the risk of scratching mold surfaces, mirror rollers, or wafer substrates. It is well suited for measurement applications in semiconductor and precision equipment processes.

Product Advantages

- 6-in-1 efficient design: One tool integrates six common gap thicknesses ranging from 0.10 mm to 0.20 mm, compact and easy to carry, with clear and intuitive thickness selection.

- Non-scratching contact: PEEK has lower hardness than metal, preventing scratches or particle generation when contacting precision molds, optical components, or wafer surfaces.

- High temperature and chemical resistance: Suitable for use in environments up to 240 °C, with excellent resistance to most chemical solvents, acids, and alkalis, making it ideal for harsh process conditions.

- Excellent dimensional stability: Maintains high thickness accuracy even under temperature fluctuations, ensuring reliable measurement results.

- Non-magnetic and electrically insulating: Suitable for electronic equipment and semiconductor processes without magnetic interference.

Applications

- Semiconductor / Optoelectronics: Wafer transport mechanism gap adjustment and leveling alignment.

- Precision mold industry: Mold closing gap inspection and slider clearance measurement.

- Automation equipment: Robotic arm assembly calibration and roller parallelism adjustment.

- Electronics assembly: Tolerance inspection during component assembly.

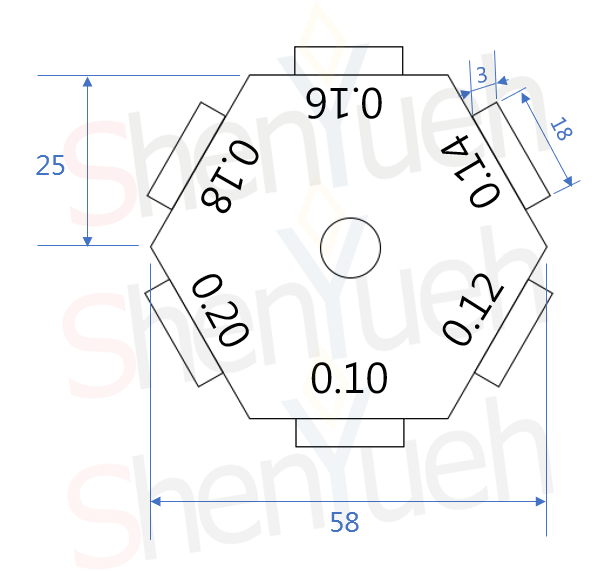

Product Specifications

| Model | Specification | Thickness (mm) | Material |

|---|---|---|---|

| HEXG-0.1-0.2 | High-Precision Type (0.02 mm increment) | 0.10 / 0.12 / 0.14 0.16 / 0.18 / 0.20 | PEEK |

| HEXG-0.2-0.55 | High-Precision Type (0.02 mm increment) | 0.20 / 0.22 / 0.24 0.26 / 0.28 / 0.30 | PEEK |

| HEXG-0.5-0.55 | Standard Type (0.05 mm increment) | 0.30 / 0.35 / 0.40 0.45 / 0.50 / 0.55 | PEEK |

| HEXG-50100 | General-Purpose Type (0.10 mm increment) | 0.50 / 0.60 / 0.70 0.80 / 0.90 / 1.00 | PEEK |

※ All dimensions are in millimeters. Thickness accuracy can be controlled within a tolerance of ±0.01 mm.

※ The overall thickness is fixed at 5 mm. The protruding thickness is adjusted according to the values listed in the “Thickness (mm)” column.

※ For other dimensions, specifications, thickness ranges, or engraving combinations, please fill out the form below to contact us.

Our PEEK hexagonal feeler gauges are manufactured with thickness markings in μm and are suitable for use in various operating environments. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, PEEK Hexagonal Feeler Gauge, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.