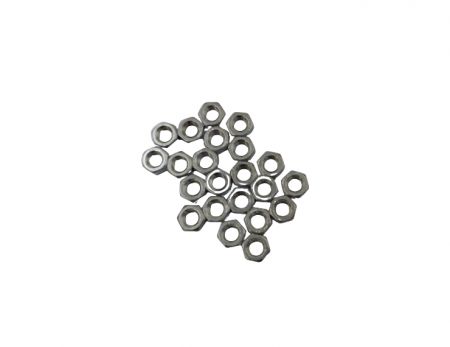

Molybdenum Screws|Nuts|Washers

Shen-Yueh manufactures fasteners (screws, nuts, and washers) made of molybdenum material. Our molybdenum screws not only possess excellent high-temperature resistance (able to withstand temperatures above 2000 degrees), outstanding corrosion resistance against most chemicals, but also have excellent wear resistance and high hardness, which can extend the locking life. Whether you are dealing with aviation, nuclear energy, vacuum systems, or other high-temperature applications, we can provide you with stable solutions and consulting services. Please feel free to fill out the contact form below, and we will serve you as soon as possible.

Advantages of Molybdenum Screws

- High-Temperature Stability: Molybdenum has a very high melting point, reaching 2623K (2350°C), making molybdenum screws exhibit excellent performance and stability in high-temperature environments.

- Corrosion Resistance: Molybdenum has good corrosion resistance and can withstand the corrosion of most acids and bases. This makes molybdenum screws suitable for use in chemically harsh environments.

- High Hardness and Wear Resistance: Molybdenum has higher hardness, hence the screws made from it have higher wear resistance, suitable for long-term, high-strength working environments.

- Oxidation Resistance: In high-temperature environments, molybdenum can form a stable oxide layer, which helps improve its oxidation resistance and extend the lifespan of the screws.

- High Strength and Toughness: Molybdenum has high strength and toughness, maintaining good mechanical properties even in extreme environments.

- Low Coefficient of Thermal Expansion: Molybdenum has a lower coefficient of thermal expansion, meaning its volume changes less with temperature variations, which is very important for some precision devices and high-temperature applications.

- Good Electrical Conductivity: Molybdenum has good electrical conductivity, making molybdenum screws also suitable for electronic and electrical applications.

Applications of Molybdenum Screws

1. High-Temperature Environments: Molybdenum screws exhibit superior performance in high-temperature environments, making them commonly used in aerospace, aviation engines, rockets, spark plugs, high-temperature furnaces, and other high-temperature industrial applications.

2. Vacuum Systems: The use of molybdenum screws in vacuum systems is due to their chemical stability and low volatility. They are typically used in the manufacture of vacuum-sealed systems, vacuum furnaces, and other equipment requiring a stable vacuum environment.

3. Nuclear Applications: Molybdenum screws can be used in nuclear reactors, nuclear power plants, and other nuclear applications, as they can withstand high radiation and high-temperature environments.

4. Semiconductor Industry: The high conductivity and chemical stability of molybdenum screws make them suitable for use in semiconductor manufacturing equipment, such as in plasma etching machines and thin-film deposition equipment.

5. Chemical Industry: Due to the corrosion resistance of molybdenum, molybdenum screws can be used in the chemical industry, especially in equipment handling corrosive chemicals.

6. Optics and Laser Systems: Molybdenum screws are used in some optical and laser systems, such as high-power laser equipment, where they need to withstand high energy output and high temperatures.

7. Thermal Dissipation Materials: Molybdenum has good thermal conductivity, so in applications requiring heat dissipation, such as cooling systems for high-power electronic components, molybdenum screws can be used as thermal dissipation materials.

8. High-Performance Mechanical Structures: Although molybdenum is a brittle material, its strength can be improved in certain shapes. Therefore, in some mechanical structures requiring high temperature and high strength, molybdenum screws can play a role.

Product Specifications

● Material: Molybdenum

● Screw Head Type: Hex Socket, Hex Head, Slotted Pan Head

● Screw Thread Type: Metric (M2~M20), Imperial (UNC, UNF)

● Nut Thread Type: Metric (M2~M20), Imperial (UNC, UNF)

● Flat Washers: Metric (M2~M20)

● Packaging: 10PCS / PACK

Shen-Yueh offers a variety of molybdenum fastener sizes and specifications (screws, nuts, washers) and custom quantities. Please fill out the form below or contact us to learn more about our product details

Shen-Yueh provides stable molybdenum screw materials, capable of withstanding temperatures above 2000 degrees. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, Molybdenum Screws|Nuts|Washers, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.