Polypropylene PP Plastic Machining

Corrosion-Resistant Solutions Designed for Semiconductor Equipment Needs

We offer comprehensive material selection and CNC precision machining services for polypropylene (PP), supporting NPP, WPP, and GPP grades. Our expertise enables the development of customized components suitable for various semiconductor process environments. Known for its excellent acid and alkali resistance, chemical stability, and machinability, PP is widely used in semiconductor equipment such as cleaning tanks, chemical tanks, spray systems, rollers, electroplating modules, and equipment enclosures.

Material Types & Applications

Material Type | Application Scenario | Feature Description |

NPP (Natural PP) | Precision parts, rollers, chamfer components | High cleanliness and dimensional stability; ideal for process contact zones |

WPP (White PP) | Tank structures, encapsulated parts | Excellent corrosion resistance with high visual consistency |

GPP (Glass-filled PP) | Support structures, mechanical piping, slide rails | High rigidity and deformation resistance; suitable for high-strength applications |

Material Properties

- Strong resistance to acid, alkali, and chemical corrosion

- Lightweight for easy installation and maintenance

- Highly flexible for small-batch or non-standard component processing

- Heat resistance: continuous use at 90°C, up to 110°C for short periods

- Anti-static grades available for use in ESD-sensitive areas

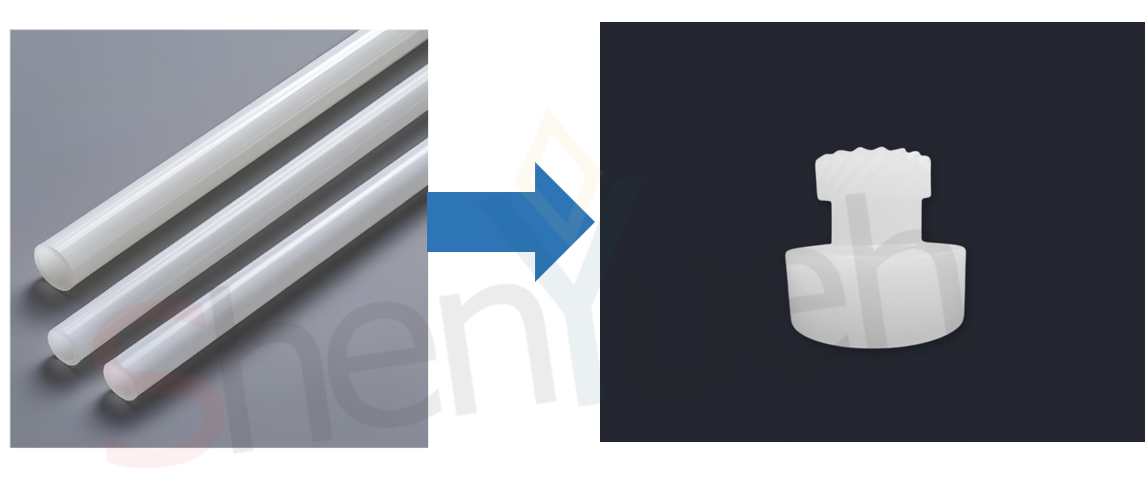

Processing Example|From Raw Material to Customized Parts

Every processed component begins with the appropriate PP material (NPP / WPP / GPP). Based on customer-provided drawings or samples, we manufacture equipment parts that meet application conditions through precise machining. Whether it's spray piping, tank assemblies, roller modules, or other structural parts, we offer material recommendations and machining solutions tailored to the application environment and structural requirements.

Example below:

Left: Raw PP rod | Right: Finished customized part

You are welcome to send us your drawings or samples. We will assess the machining feasibility and provide suitable material and manufacturing recommendations based on your needs.

Our Advantages

- Over 18 years of experience in the semiconductor industry with deep understanding of equipment and process pain points

- Capable of handling small-volume, diverse, and customized requests, with expedited scheduling available

- In-house factory and complete processing capabilities to ensure stable lead time and consistent quality

- Support for international client audits

- Engineering team available for material selection advice and structural adjustments

Applicable Uses

- Cleaning equipment, etching machines, acid and alkali tanks

- Electroplating process modules, spray and drainage piping

- Equipment enclosures, protective covers, and support systems

- Special use: Anti-static PP materials available for ESD-sensitive areas

Contact Us

Please feel free to contact us. Whether you already have complete drawings or only sample references, we can assist in feasibility assessment, suggest suitable materials, and provide clear manufacturing and quotation advice.

Email:service@sy-tech.com.tw

Or fill out the form below, and we’ll get back to you as soon as possible with dedicated support and technical assistance.

CNC PP plastic precision parts for semiconductor and TFT-LCD process equipment are made of acid-alkali resistant material. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, Polypropylene PP Plastic Machining, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.