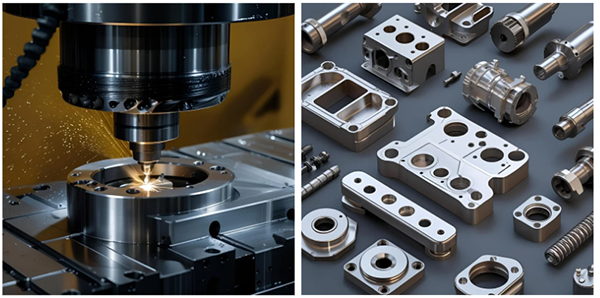

Titanium Alloy CNC Machining

CP Titanium (Grades 1–4)、Titanium Alloys (Grades 5, 7, 9)

We specialize in high-precision CNC machining of titanium alloy components that are corrosion-resistant, non-magnetic, and lightweight—ideal for critical processes in the semiconductor, optoelectronic, energy, and electronics industries. Our capabilities include handling acid/alkaline-resistant environments and complex structural requirements, helping customers improve yield and efficiency during implementation. From prototyping and reverse engineering to CNC machining and surface finishing, we rapidly align with engineering needs and support efficient volume production.

Global Collaboration × Advanced Manufacturing Support

Our titanium CNC machining expertise spans Taiwan, Japan, South Korea, Europe, and the Middle East. We provide customized solutions for challenging applications involving corrosive gases, non-magnetic environments, and extreme temperatures.

Collaboration Highlights

- Reverse engineering and sample-based drawing support—no blueprint required

- Flexible production for samples, small batches, and frequent design iterations

- Seamless collaboration with engineering and procurement teams for fast project execution

- Familiar with high-precision demands and global equipment integration

Suitable for global manufacturing sectors, including Saudi Arabia, UAE, Eastern Europe, and Southeast Asia

Key Industries & Sample Applications

- Semiconductor Equipment: Structural parts for wet-process tools, frames, brackets, interface modules

- Optoelectronics: Positioning modules, conductive contacts, precision non-magnetic parts

- Energy Modules: Acid/alkali-resistant parts, lightweight high-temperature structures, cooling plates and covers

- Electronics: Micro-structures, non-magnetic parts, thermal and shielding modules

Key Potential in the Petrochemical Industry

Thanks to its outstanding corrosion resistance, high strength, and non-magnetic properties, titanium alloy has gained strong recognition in global petrochemical manufacturing. It’s increasingly used as a key material for components exposed to extreme chemical and high-temperature conditions.

Application Scenarios

- Acid/alkali gas-exposed parts (e.g., H₂S or saline environments)

- Covers, flanges, and connector modules in petrochemical processes

- Neutral or non-magnetic structural parts and thin-walled components

- Transition modules and housings requiring high strength and corrosion resistance

Recommended Grades by Environment

Grade 2 / 4 (Stable Corrosion Resistance)|Grade 5 (High Strength & Structural Use)|Grade 7 (Chloride-Resistant)

We understand the logic and material selection behind titanium usage in extreme environments and are actively expanding partnerships across the Middle East and global industrial markets—aiming to become a trusted long-term supplier of precision petrochemical components.

4 Core Advantages

✉️ Application-Oriented Design & Material Guidance

Familiar with critical process environments, we assist in selecting suitable materials, machining methods, and designs to reduce trial-and-error risks.

✉️ Strong Reverse Engineering Capabilities

Even without drawings, we can recreate part dimensions and functions from samples to provide compatible replacements or spares.

✉️ Flexible Low-Volume Support

From project initiation and prototyping to pilot production, we support agile development needs.

✉️ Precision Machining & Quality Control

Standard CNC tolerances reach ±0.02mm. Combined with polishing, deburring, and clean packaging, we ensure consistent quality throughout.

Sample Machining Case

When only physical samples are available and OEM drawings are missing, we can reverse-engineer designs and rebuild parameters to precisely restore part functionality and structure.

Use Cases

- Replacement parts for discontinued OEM components

- Module upgrades for aging equipment

- Localized manufacturing to replace overseas supply, improving lead time and flexibility

Recommended Titanium Grades

Grade | Type | Composition | Key Features | Common Use Cases | Weldability | Availability |

G1 | Pure Ti | Unalloyed | Most ductile, softest, highly resistant | Medical, chemical processing | Excellent | Stable |

G2 | Pure Ti | Unalloyed | Most common, higher strength | Heat exchangers, marine parts | Excellent | Stable |

G3 | Pure Ti | Unalloyed | Stronger, harder to machine | Industrial structures | Moderate | Less common |

G4 | Pure Ti | Unalloyed | Strongest of pure grades, high corrosion resistance | Aerospace containers, supports | Fair | Moderate |

G5 | α+β Alloy | 6% Al + 4% V | High strength, widely used | Aerospace, bicycles, cutting tools | Good | Stable |

G7 | Alloyed Ti | Ti + Ru | Exceptional acid resistance | Etching tools, chlorine environments | Good | Rare |

G9 | α+β Alloy | 3% Al + 2.5% V | Excellent formability, medium hardness | Brackets, thin-walled parts | Good | Stable |

Client Testimonials|Trust that Grows with Collaboration

Clients across industries trust us for our quality consistency and flexibility:

“We’ve worked with SY for years. During the R&D sample stage, they consistently supported engineering changes quickly and offered reliable suggestions.”

– Semiconductor Equipment Developer

“Stable material quality and accurate lead times—an essential partner for our high-variation production projects.”

– Optoelectronic Production Lead

“Even though we’re overseas, SY clearly understood our specs and handled customs and packaging with ease. The onboarding was seamless.”

– Overseas Equipment Client

Contact Us for Machining Consultation & Quotation

We’re committed to helping clients implement stable, high-quality precision components with the following services:

- Quotation and machining advice based on drawings or samples

- Packaging, export, and delivery assistance

- Material selection and design recommendations

Email us at: service@sy-tech.com.tw

Your trusted partner in high-end CNC titanium machining

SHEN-YUEH's CNC high-precision, aesthetically pleasing processed titanium parts are often used in semiconductor and biochemical industries. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, Titanium Alloy CNC Machining, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.