Molybdenum Crucibles

Our Molybdenum Crucibles are fully customizable in dimensions, wall thickness, flange or sealing structures, and operating environments.Each crucible is precisely machined and strictly inspected to ensure structural stability and low contamination during melting, coating, or reaction processes — effectively reducing scrap rates while improving yield and consistency.

The crucibles are widely used in electron-beam and thermal evaporation, PVD / CVD coating, alloy melting, and crystal growth processes, meeting various high-temperature and vacuum application requirements.

Please fill out the inquiry form below to contact us — we will provide professional consultation as soon as possible.

Product Advantages

- High melting point and thermal stability: Molybdenum has a melting point up to 2623 °C and maintains structural integrity even under extreme temperatures.

- Excellent thermal conductivity: Enables fast and uniform heat transfer, improving process efficiency and material homogeneity.

- Chemical inertness and corrosion resistance: Performs stably in vacuum and inert atmospheres, reducing the risk of contamination.

- High-purity material: Made from molybdenum with 99.95% or higher purity to ensure cleanliness and reliability.

- Fully customizable process: Dimensions, thickness, and opening structure can be designed according to application requirements.

- High reliability manufacturing: Precision machining and strict quality inspection ensure dimensional accuracy and long-term durability.

Applications

- Semiconductor high-temperature processes

- Vacuum evaporation and electron beam coating systems

- Metal and rare material melting

- Chemical vapor deposition / physical vapor deposition (CVD / PVD)

- Material research and crystal growth equipment

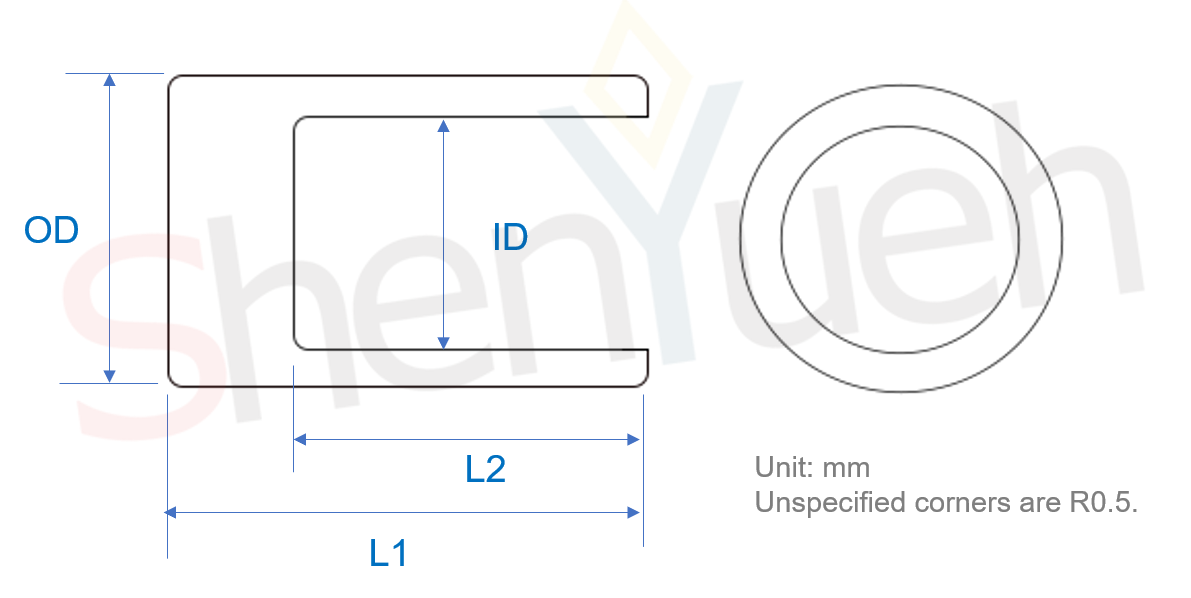

Product Specifications

- Dimension unit: mm

- Material: High purity molybdenum (purity ≥99.95%)

- Part Number Format:

MC – OD – ID – L1 – L2

Part No. | OD | ID | L1 | L2 |

MC-15-5-15-5 | 15 | 5 | 15 | 5 |

MC-20-10-20-10 | 20 | 10 | 20 | 10 |

MC-25-15-25-15 | 25 | 15 | 25 | 15 |

MC-30-20-30-20 | 30 | 20 | 30 | 20 |

MC-35-25-35-25 | 35 | 25 | 35 | 25 |

MC-40-30-40-30 | 40 | 30 | 40 | 30 |

※In addition to the listed standard sizes, we can customize different dimensions, structures, or thicknesses according to customers’ actual application needs, or manufacture based on provided drawings.

Contact Us

If you wish to improve process stability or learn more about the customized design and material options of molybdenum crucibles for various high-temperature and vacuum applications, please feel free to contact us.

Email: service@sy-tech.com.tw

You may also fill out the inquiry form below, and our team will contact you shortly to provide the most suitable technical advice and support for your process needs.

High purity molybdenum crucible | For vacuum evaporation, PVD, CVD, and crystal growth processes | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, Molybdenum Crucibles, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.