VESPEL Plastic Machining

Engineered for High Temperatures, Vacuum, and Process Stability

Suitable for plasma chambers, wafer handling, thermal insulation, and chemically resistant etching environments.

We specialize in precision machining of Vespel® engineering plastics, particularly for critical components used in semiconductor equipment operating under high temperature, high vacuum, and low particle environments. With in-depth knowledge of various Vespel grades, we offer proven machining expertise and strict process control to support customers from prototyping to full-scale production, meeting the high standards of advanced processes in terms of accuracy, stability, and material performance.

To learn more about our Vespel machining services, please contact us using the form below. We are here to assist you with dedication.

Support for Multiple Vespel® Grades

We offer machining services for various Vespel® grades, including:

Grade | Properties & Recommended Applications |

SP-1 | High-purity polyimide with excellent insulation, ideal for high vacuum and plasma chamber applications. |

SCP-5000 | Modified polyimide with higher strength and stability, suitable for load-bearing and structural support uses. |

CR-6100 / CR-6110 | Commonly used in semiconductor etching equipment, combining thermal stability and chemical resistance. |

*If you require other grades or branded materials, we can assist with feasibility evaluation and processing.

Machining Capabilities & Features

- Supports multi-axis CNC machining and high-precision cutting for complex geometries and thin-walled parts

- Experienced in high-temperature and vacuum conditions; machining methods are tailored to material properties

- Proficient in reverse engineering, prototyping, and multi-spec integration

- Familiar with structural requirements of major equipment brands such as AMAT, TEL, and Lam

- Flexible low-volume production support to reduce customer inventory pressure and development risk

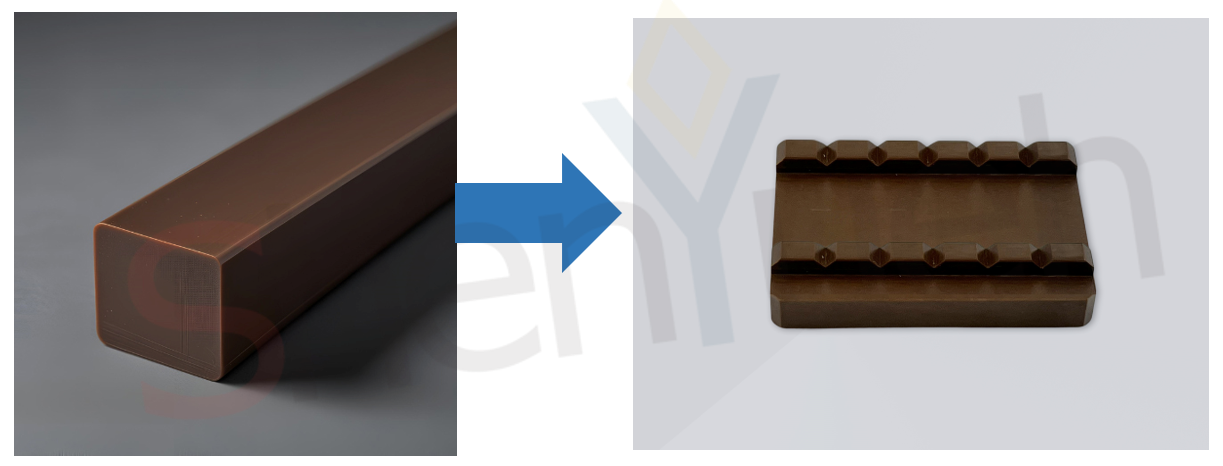

Machining Example | From Raw Material to Custom Parts

In actual projects, we often assist customers in material selection, structural verification, and dimensional conversion based on their drawings, samples, or usage conditions—delivering stable machining results. From raw stock to turning/milling, edge finishing, inspection, and packaging, we provide full-process support.

For example:

- Confinement Rings used in etcher chambers must remain stable under high temperatures and corrosive gases

- End Effector Pads on robotic arms require shock absorption, low particle generation, and wafer-safe contact

- Lift Pin Guides in wafer lift systems must provide precise alignment and wear resistance

Left: raw stock; Right: finished custom part

Please provide drawings or samples—we will evaluate feasibility and recommend suitable materials and production options.

Common Semiconductor Equipment Applications

Vespel® materials offer stable performance and are widely used in various semiconductor systems, including:

Machined Part | Application Area | Function |

Confinement Ring | Etcher chamber | Controls gas flow field; heat- and corrosion-resistant structure |

Insulator Bushing | Insulation areas / dielectric isolation components | Provides electrical isolation and chemical resistance |

Lift Pin Guide | Wafer lifting guide system | Ensures alignment, wear resistance, and low particle generation |

End Effector Pad | Robotic arm end | Shock absorption and wafer protection; prevents surface contamination |

Thermal Spacer | Thermal isolation between chamber structures | Stabilizes heat transfer and avoids thermal interference in precision assemblies |

Contact Us

If you're developing or replacing parts made with Vespel® materials, we welcome you to share your drawings, samples, or application details.

We’ll help confirm the suitable grade and machining requirements, delivering reliable and stable manufacturing solutions.

Email: service@sy-tech.com.tw

Please fill out the form below or email us to share your needs—we’ll be glad to provide the right machining recommendations.

Vespel plastic machining with customized solutions tailored to customer requirements. | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, VESPEL Plastic Machining, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.