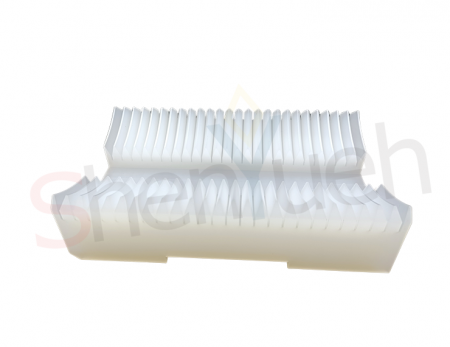

TR-Robot Pushing comb

Wafer Pushing and Guiding Component for Semiconductor Automation Equipment

Our TR-ROBOT PUSHING COMB is manufactured from high-performance fluoropolymer engineering plastics and is specifically designed for wafer pushing, guiding, and positioning applications in semiconductor automation equipment.

With a structured guiding surface and symmetrical groove design, it provides stable support during wafer or substrate transfer, reducing misalignment and edge damage while ensuring smooth and consistent pushing motion.

The selected fluoropolymer materials feature low moisture absorption, excellent chemical resistance, and high dimensional stability, making them suitable for wet processes and high-cleanliness environments. The component maintains structural precision over long-term operation, meeting semiconductor equipment requirements for low friction, low outgassing, and high reliability.

Product Advantages

- Excellent chemical resistance: suitable for strong acids, alkalis, and organic solvent environments

- Stable thermal performance: reliable for long-term use under process temperature variations

- Low-friction contact: reduces the risk of wafer scratching and edge damage

- Guiding structure design: ensures stable pushing motion with minimal deviation

- Low moisture absorption and dimensional stability: resistant to deformation caused by humidity or temperature changes

- Low outgassing characteristics: meets high-cleanliness process requirements

Applications

- Robot Transfer Modules for semiconductor automation equipment

- Wafer pushing and positioning in Load Ports and Buffer Stations

- End guiding and protective components for wafer handling systems

Product Specifications

Item | Customization Description |

Material Selection | High-purity fluoropolymer materials (PFA, PTFE, PVDF) or other high-performance engineering plastics selected based on process requirements |

Chemical Resistance | Material and structural design optimized for strong acids, strong alkalis, or strong oxidizing environments according to actual process conditions |

Machining Precision | High-precision CNC machining ensures consistent tooth geometry, dimensional stability, and smooth surface finish |

Applicable Sizes | Custom-designed to support 4"–12" wafers or special wafer/substrate sizes based on equipment and process requirements |

If you have equipment drawings, samples, or specific process requirements, please feel free to contact us.

We will evaluate material selection and structural configuration based on actual operating conditions and provide dedicated custom design recommendations.

Manufactured from high-performance fluoropolymer engineering plastics, designed for semiconductor automated wafer pushing applications | PEEK & PI Plastic CNC Machining Manufacturer | Shen-Yueh (SYT)

Located in Taiwan since 2006, Shen-Yueh Technology co., Ltd. has been a CNC plastic and metal machining manufacturer in Metal Processing Industry. Their main CNC machining supplies include, TR-Robot Pushing comb, CNC plastic machining, air knife productions, PEEK plastic machining and fabrication, CNC metal machining, Polyimide (PI) plastic CNC machining and milling, and bearing, which are delivered with expanded production capacity, short lead time, and better customer service.

SHEN-YUEH is composed of semiconductor equipment and machining design personnel who cooperate with the CNC professional technician team, which has more than 10 years of experience. The production process is carried out in accordance with ISO and a clean factory environment to provide excellent professional consultations and service! We focus on CNC parts processing and equipment transformation experience in the semiconductor and panel industries (since 2006). For more than 10 years, we have solved problems of design, development, and organization optimization and increased the lifecycle of parts, reducing costs for many customers and quickly providing manufacturing samples to reduce customer development time.

Shen-Yueh (SYT) has been offering high-quality equipment part manufacturing for semiconductor manufacturing department, panel and comprehensive industries, both with advanced engineering technology and 13 years of experience, Shen-Yueh (SYT) ensures each customer's demands are met.